Welcome to the Hankison Air Dryer Manual. This guide provides essential information for installing‚ operating‚ and maintaining Hankison refrigerated air dryers. These systems effectively remove moisture‚ oil vapor‚ and contaminants from compressed air‚ ensuring optimal performance and protection of pneumatic equipment. The manual is designed to help users understand the dryer’s functionality‚ safety precautions‚ and maintenance requirements for prolonged efficiency and reliability.

1.1 Overview of Hankison Air Dryers

Hankison air dryers are high-performance refrigerated systems designed to remove moisture‚ oil vapor‚ and contaminants from compressed air. These dryers protect pneumatic equipment‚ instruments‚ and tools from damage caused by humidity and other harmful substances. Available in various models‚ Hankison dryers offer advanced features like energy efficiency‚ compact design‚ and reliable operation. They are engineered to meet ISO 8573.1 air quality standards‚ ensuring optimal performance for industrial and commercial applications. Their robust construction and user-friendly controls make them a popular choice for maintaining clean and dry compressed air systems.

1.2 Importance of Using the Manual

Using the Hankison Air Dryer Manual is crucial for ensuring safe and effective operation. It provides detailed instructions for installation‚ maintenance‚ and troubleshooting‚ helping users maximize efficiency and longevity. The manual includes safety precautions‚ parts lists‚ and diagnostic guidance‚ essential for preventing malfunctions and ensuring compliance with industry standards. By following the manual‚ users can avoid costly repairs and maintain optimal performance of their compressed air system‚ ensuring reliability and productivity in industrial applications.

1.3 Structure of the Manual

This manual is organized into clear sections to guide users through the safe and efficient use of the Hankison Air Dryer. It begins with an introduction‚ followed by installation guidelines‚ operating procedures‚ maintenance instructions‚ and troubleshooting tips. Additional sections cover technical specifications‚ safety precautions‚ warranty details‚ and resources for further support. Each chapter is designed to provide comprehensive information‚ ensuring users can easily navigate and understand the dryer’s operation‚ maintenance‚ and optimal performance.

2.0 Installation Guidelines

Proper installation is crucial for optimal performance. Ensure the dryer is mounted level‚ connected correctly‚ and positioned downstream of an aftercooler or separator to prevent liquid water ingress.

2.1 Pre-Installation Checks

Before installing the Hankison air dryer‚ ensure the inlet air is free from liquid water and does not exceed 122°F. Verify that the dryer is installed downstream of an aftercooler or separator to prevent liquid water ingress. Check the power supply matches the dryer’s requirements and ensure compatibility with the compressed air system. Inspect all components for damage and ensure proper grounding. Familiarize yourself with local safety codes and standards‚ such as NFPA‚ to ensure compliance. Proper preparation ensures safe and efficient operation of the dryer.

2.2 Mounting the Air Dryer

Mount the Hankison air dryer on a level‚ sturdy surface using appropriate fasteners. Ensure the unit is securely anchored to prevent vibration and movement. Proper grounding is essential for safety and optimal performance. Position the dryer away from direct sunlight and flammable materials. Align the inlet and outlet ports with the compressed air system‚ ensuring correct airflow direction. Double-check all connections for tightness and verify that the dryer is installed downstream of an aftercooler or separator to prevent liquid water ingress. Proper installation ensures reliable operation and extends the dryer’s lifespan.

2.3 Connecting the Air Dryer

Connect the Hankison air dryer to the compressed air system by attaching the inlet and outlet ports. Ensure the air flows in the correct direction as indicated on the unit. Use appropriate fittings and tubing to prevent leaks and contamination. Secure all connections tightly to avoid pressure drops. Install the dryer downstream of an aftercooler or separator to prevent liquid water ingress. Check for blockages in the air supply lines and ensure proper drainage. Follow the manual for specific electrical connections‚ if applicable‚ and consult a qualified technician for assistance if needed.

2.4 System Arrangement Recommendations

Install the Hankison air dryer downstream of an aftercooler or separator to ensure inlet air temperature does not exceed 122°F and contains no liquid water. Position the dryer in a well-ventilated area‚ away from direct sunlight and heat sources. Ensure proper drainage of condensate from the system. Avoid bends or restrictions in piping to maintain optimal airflow. The dryer should be mounted level and secure to prevent vibration. Follow the recommended system layout in the manual to ensure efficient operation and minimize pressure drops. Consult the manual for specific piping and installation guidelines.

3.0 Operating the Hankison Air Dryer

Ensure proper startup‚ monitor operation‚ and follow shutdown procedures. Regularly inspect and maintain the dryer to optimize performance and extend equipment lifespan.

3.1 Startup Procedures

Before starting the Hankison air dryer‚ ensure all installation steps are completed and the system is properly connected. Check for any damage or leaks in the connections. Power up the dryer and allow it to initialize. Ensure the inlet air temperature does not exceed 122°F and is free of liquid water. Refer to the control panel for operational status. Start the dryer in the correct mode as specified in the manual. Allow the system to stabilize before full operation. Always follow safety guidelines and manufacturer recommendations during startup.

3.2 Normal Operation and Monitoring

During normal operation‚ the Hankison air dryer efficiently removes moisture and contaminants from compressed air. Monitor the inlet air temperature‚ ensuring it does not exceed 122°F‚ and check for liquid water‚ which can impair performance; Regularly inspect the control panel for operational status and alarms. Ensure proper function of the drain system to prevent water accumulation. Maintain consistent airflow and pressure levels as recommended. Schedule routine checks of filters and refrigerant levels to ensure optimal performance and prevent unexpected shutdowns. Always adhere to safety guidelines during monitoring and maintenance.

3.3 Shutdown Procedures

To safely shut down the Hankison air dryer‚ first switch off the power supply and allow the system to cool. Ensure all compressed air lines are depressurized to prevent residual pressure. Drain any accumulated condensate from the system. Secure the area to avoid accidental restart. Perform a visual inspection for leaks or damage. Document the shutdown process for maintenance records. Always follow the manufacturer’s guidelines to ensure safety and prevent equipment damage during shutdown procedures.

3.4 Understanding the Control Panel

The control panel of the Hankison air dryer is designed for easy monitoring and operation. It features LED indicators for system status‚ pressure gauges‚ and temperature displays. The panel includes switches for power control and buttons for adjusting settings. Alarm indicators alert users to issues like high pressure or low refrigerant levels. Regularly check the panel to ensure proper operation and address any alerts promptly. This centralized interface helps maintain efficiency and safety‚ ensuring optimal performance of the air dryer system. Always refer to the manual for detailed instructions on panel functions and troubleshooting.

4.0 Maintenance and Service

Regular maintenance ensures optimal performance and longevity of your Hankison air dryer. Key tasks include cleaning or replacing filters‚ checking refrigerant levels‚ and replacing wearable parts. Refer to the manual for detailed schedules and procedures.

4.1 Routine Maintenance Checks

Regular maintenance is crucial for ensuring the Hankison air dryer operates efficiently. Begin by inspecting the air filter for dirt or debris‚ cleaning or replacing it as needed. Next‚ check the refrigerant levels to ensure proper cooling function. Inspect all hoses and connections for leaks or damage‚ tightening any loose fittings. Additionally‚ monitor the inlet air temperature‚ ensuring it does not exceed 122°F to prevent liquid water entry. Finally‚ review the control panel for any error codes or alerts‚ addressing them promptly to avoid system downtime. Consistency in these checks will help maintain optimal performance and extend the dryer’s lifespan.

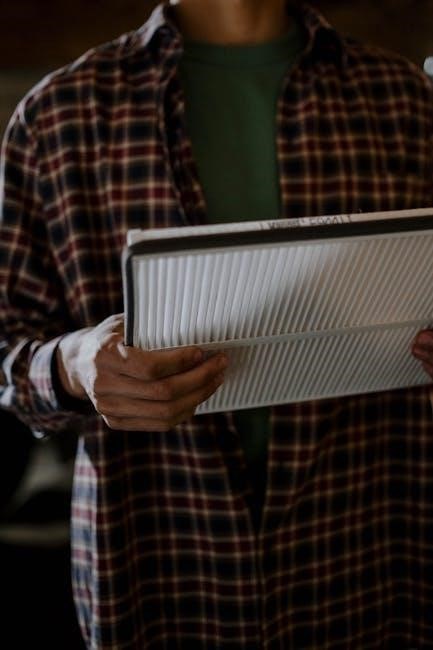

4.2 Filter Maintenance and Replacement

Regular filter maintenance is essential for optimal performance of the Hankison air dryer. Inspect the filter monthly and replace it every 6 months or as needed. A clogged filter can reduce airflow and efficiency‚ potentially allowing contaminants into the system. To replace the filter‚ turn off the power‚ remove the housing‚ and install a new filter. Always use genuine Hankison replacement parts to ensure compatibility and effectiveness. Proper disposal of the old filter is recommended to prevent environmental contamination. Refer to the manual for specific instructions and guidelines.

4.3 Refrigerant Management and Checks

Proper refrigerant management is critical for the efficiency and longevity of the Hankison air dryer. Regularly inspect the refrigerant lines for leaks or damage. Use a refrigerant leak detector to ensure system integrity. Check the refrigerant level and recharge only with the specified type‚ as indicated in the manual. Improper refrigerant levels or incorrect types can lead to reduced performance or system damage. Always follow safety protocols when handling refrigerants‚ and refer to the manual for detailed procedures and guidelines.

4.4 Replacement of Wearable Parts

Regular replacement of wearable parts is essential for maintaining the performance and longevity of your Hankison air dryer. Filters‚ seals‚ and other components should be replaced at intervals specified in the manual. Always use genuine Hankison parts to ensure compatibility and reliability. Refer to the manual’s parts list for correct identification and ordering. Improper installation or using non-approved parts can lead to reduced efficiency or system damage. Follow the manual’s guidelines for replacement procedures to maintain optimal operation and prevent downtime.

5.0 Troubleshooting Common Issues

This section addresses common problems with Hankison air dryers‚ such as moisture in the inlet air‚ improper installation‚ or filter blockages‚ and provides diagnostic solutions to resolve them effectively.

5.1 Identifying Common Problems

Common issues with Hankison air dryers include moisture in the inlet air‚ high pressure drop‚ or condenser blockage. Symptoms like reduced airflow‚ icing‚ or increased dew point indicate potential malfunctions. Regularly check for filter blockages‚ improper installation‚ or refrigerant leaks; Monitoring system performance and addressing alarms promptly helps identify problems early. Always refer to the manual for specific troubleshooting guides tailored to your model. Early detection and resolution of these issues ensure optimal performance and extend the lifespan of your Hankison air dryer system.

5.2 Diagnostic Steps for Malfunctions

Diagnosing malfunctions in Hankison air dryers involves systematic checks. Start by reviewing alarm codes and monitoring system performance. Inspect the inlet air for moisture or contamination‚ and check for blockages in filters or condensers. Verify refrigerant levels and ensure proper airflow. Measure pressure drops across components and compare with manufacturer specifications. Use gauges to check inlet and outlet pressures‚ and assess the condition of sensors and valves. These steps help pinpoint issues like faulty compressors or malfunctioning controllers‚ ensuring accurate troubleshooting and timely resolution to maintain efficiency and reliability. Regular diagnostics prevent major system failures.

5.3 Solutions for Frequently Encountered Issues

Common issues with Hankison air dryers include high pressure drop‚ low refrigerant levels‚ and condenser inefficiency. To address these‚ clean or replace the pre-filter‚ inspect for blockages‚ and ensure proper airflow. For refrigerant issues‚ check for leaks‚ recharge as needed‚ and verify system charging procedures. Condenser inefficiency can be resolved by cleaning the unit and ensuring adequate ventilation. Regular maintenance‚ such as filter replacements and sensor checks‚ prevents recurring problems. Addressing these issues promptly ensures optimal performance and extends the lifespan of the dryer.

6.0 Technical Specifications

The Hankison air dryer is designed to meet ISO 8573.1 Class 5 standards‚ ensuring efficient moisture removal. It features advanced refrigeration systems‚ durable construction‚ and precise temperature control for optimal performance.

6.1 Key Features of the Hankison Air Dryer

The Hankison air dryer boasts an advanced refrigeration system designed to efficiently remove moisture from compressed air. It features a robust construction with high-quality materials‚ ensuring durability and long-term reliability. The dryer includes a microprocessor-based control panel for precise temperature and humidity management. Its compact design allows for easy installation and integration into existing air systems. Additionally‚ the dryer operates quietly and is energy-efficient‚ making it suitable for industrial and commercial applications. These features ensure consistent performance and compliance with industry standards for air quality.

6.2 Performance Metrics and Standards

The Hankison air dryer is designed to meet ISO 8573.1 Class 5 standards‚ ensuring high-quality compressed air. It operates within a temperature range of 35°F to 100°F and maintains a pressure dew point of 50°F maximum. The dryer is capable of handling flow capacities up to 1‚000 SCFM and operates at a maximum pressure of 250 PSIG. Its energy-efficient design minimizes energy consumption while delivering consistent performance. Compliance with industry standards ensures reliability and optimal air quality‚ making it suitable for demanding industrial applications. These metrics guarantee superior performance and durability.

6.3 Compliance with Industry Regulations

Hankison air dryers are designed to comply with industry regulations‚ including ISO 8573.1 Class 5 standards for compressed air quality. They meet UL and CE certifications‚ ensuring safety and reliability in global markets. The dryers adhere to environmental regulations and energy efficiency standards‚ reducing operational costs and ecological impact. Compliance with these regulations ensures that Hankison air dryers align with industry best practices‚ providing users with a reliable and environmentally responsible solution for compressed air treatment. This compliance makes them suitable for a wide range of industrial applications.

7.0 Safety Precautions

Always wear protective gear when handling the air dryer. Ensure proper grounding to prevent electrical hazards. Avoid exposing the unit to extreme temperatures or liquid water ingress.

7.1 General Safety Guidelines

Always wear protective gear‚ including safety glasses and gloves‚ when handling the air dryer. Ensure proper installation and grounding to prevent electrical hazards. Avoid exposing the unit to extreme temperatures or liquid water‚ as this can damage the system. Regularly inspect the dryer and its components for signs of wear or damage. Follow all manufacturer instructions and safety standards to ensure safe operation. Proper ventilation is essential to prevent the accumulation of harmful gases. Adhere to these guidelines to maintain a safe working environment and prolong the lifespan of the equipment.

7.2 Handling Hazardous Materials

When handling hazardous materials related to the Hankison air dryer‚ always follow proper safety protocols. Wear appropriate personal protective equipment (PPE)‚ including gloves and safety goggles‚ to avoid exposure to harmful substances. Ensure the safe handling of refrigerants and chemical substances used in the system. Dispose of any hazardous materials according to local and environmental regulations. Properly contain and label substances to prevent accidental exposure or contamination. Always refer to the material safety data sheets (MSDS) for specific handling instructions. Adhere to these guidelines to maintain a safe working environment and prevent potential hazards.

7.3 Emergency Procedures

In case of emergencies involving the Hankison air dryer‚ immediately switch off the power supply and evacuate the area. For refrigerant leaks‚ ventilate the space thoroughly and avoid open flames. If the system overheats or experiences overpressure‚ activate the safety relief valve and allow the system to cool down. In the event of a fire‚ use dry chemical or carbon dioxide extinguishers. Always contact professional assistance and follow local emergency response protocols. Ensure all safety measures are taken to prevent injury or further damage to the equipment.

8.0 Warranty and Support

This section outlines the warranty coverage for Hankison air dryers‚ including duration and scope. It also provides details on how to contact customer support and access online resources for troubleshooting and maintenance.

8.1 Warranty Coverage Details

The Hankison air dryer is backed by a comprehensive warranty program. The standard warranty covers parts and labor for a specified period‚ ensuring protection against manufacturing defects. Coverage details‚ including duration and scope‚ are outlined in the manual. Proper installation and maintenance‚ as per the manual‚ are required to maintain warranty validity. Misuse or failure to adhere to guidelines may void the coverage. For detailed terms and conditions‚ refer to the manual or contact the manufacturer directly. Keeping records of purchase and maintenance is recommended for warranty claims.

8.2 Contacting Customer Support

For assistance with your Hankison air dryer‚ contact customer support through the official website or the provided contact details in the manual. Support is available to address inquiries‚ troubleshooting‚ and warranty-related issues. Ensure to have your product serial number and purchase details ready for efficient service. Online resources‚ including FAQs and downloadable guides‚ are also accessible to help resolve common issues independently. Prompt and professional support is committed to ensuring optimal performance and satisfaction with your Hankison air dryer system.

8.3 Accessing Online Resources

Access comprehensive online resources for your Hankison air dryer through the official manufacturer’s website. Download the PDF manual‚ troubleshooting guides‚ and technical specifications. Explore FAQs‚ instructional videos‚ and software tools for enhanced system management. Register your product to gain exclusive access to premium support materials. Stay updated with the latest firmware and software updates to ensure optimal performance. Utilize these resources to resolve issues‚ optimize maintenance‚ and maximize the lifespan of your Hankison air dryer system.

9.0 Conclusion

This concludes the Hankison Air Dryer Manual. By following the guidelines‚ you ensure efficient‚ reliable operation and longevity of your system; Refer to online resources for further support.

9.1 Summary of Key Points

The Hankison Air Dryer Manual provides comprehensive guidance for optimal performance and longevity. Key points include proper installation‚ regular maintenance‚ and adherence to safety protocols. The manual emphasizes the importance of removing moisture and contaminants to protect pneumatic systems. It also outlines troubleshooting steps for common issues and highlights the need for routine checks on filters and refrigerants. By following the manual‚ users can ensure efficient operation‚ compliance with industry standards‚ and minimal downtime. Refer to the manual for detailed procedures and support resources to maximize system efficiency and reliability.

9.2 Final Tips for Optimal Performance

To achieve optimal performance with your Hankison air dryer‚ ensure regular maintenance schedules are followed‚ including filter replacements and refrigerant checks. Monitor system performance metrics to identify potential issues early. Always adhere to the manufacturer’s guidelines for installation and operation. Avoid exposing the dryer to extreme temperatures or contaminants. Keep the inlet air dry and free of liquid water to prevent efficiency loss. Stay updated with industry standards and best practices for compressed air treatment. Proper care and adherence to these tips will extend the lifespan and efficiency of your Hankison air dryer system.

9.3 Importance of Regular Maintenance

Regular maintenance is essential to ensure the Hankison air dryer operates efficiently and effectively. It prevents unexpected breakdowns‚ reduces repair costs‚ and extends the system’s lifespan. Key tasks include checking and replacing filters‚ inspecting refrigerant levels‚ and adhering to the recommended maintenance schedule. Proper upkeep ensures the dryer removes moisture and contaminants effectively‚ safeguarding your compressed air system. Regular maintenance also helps maintain optimal performance and prevents potential issues before they escalate. Always refer to the manual for specific guidelines and procedures to keep your Hankison air dryer in prime condition.

10.0 Additional Resources

For further assistance‚ download the Hankison Air Dryer Manual PDF or visit the official SPXFLOW website for related documentation‚ guides‚ and customer support resources.

10.1 Downloading the PDF Manual

To access the Hankison Air Dryer Manual in PDF format‚ visit the official SPXFLOW website or authorized distributors. Use specific model numbers like HPRP or HHE Series in your search. The PDF manual includes detailed installation‚ operation‚ and maintenance instructions. Ensure to download from trusted sources to avoid incomplete or incorrect information. The PDF format allows easy printing and digital access‚ providing a comprehensive guide for optimal use of your Hankison air dryer system. Always verify the manual corresponds to your specific model for accuracy.

10.2 Related Documentation and Guides

Alongside the main manual‚ additional resources like product brochures‚ technical bulletins‚ and application guides are available. These documents provide detailed insights into specific models such as the HPRP‚ HHE‚ and HSHD Series. They cover performance metrics‚ compliance standards‚ and best practices for installation and maintenance. Visit the SPXFLOW website or contact authorized distributors to access these materials. These supplementary guides enhance your understanding of Hankison air dryers‚ ensuring optimal performance and compliance with industry regulations. They are available in PDF format for easy reference and printing.

10.3 Manufacturer’s Official Website

The official SPXFLOW website provides comprehensive resources for Hankison air dryers‚ including downloadable PDF manuals and product brochures. Visit the site to access detailed technical specifications‚ instructional guides‚ and customer support information. The website is a valuable resource for understanding the full range of Hankison air treatment solutions and ensuring compliance with industry standards. By exploring the official website‚ users can find everything needed to optimize the performance and maintenance of their Hankison air dryers.

Leave a Reply